After a month of use, the Bambu Lab A1 Combo powered by WOL3D has proven to be a remarkable 3D printer that balances accessibility, performance, and innovation. Its easy assembly, robust build, and seamless software integration make it a joy to use, while the AMS Lite adds a creative edge with multi-colour printing. The speed, precision, and minimal noise level set it apart from older models like the Creality Ender 3 V2, though its larger footprint and occasional print failures due to external factors are minor drawbacks. I’ll continue testing the A1 Combo powered by WOL3D over the next six months, exploring more materials and complex projects, and will share an updated experience. For now, it’s a best choice for anyone looking to upgrade their 3D printing game.

-

Build & Design

-

Performance

-

Value for money

3D printing has transitioned from a niche hobby to a widely accessible technology that empowers creators, hobbyists, and professionals. The Bambu Lab A1 Combo powered by WOL3D is a standout example of this innovation. Its multi-colour printing capability, enabled by the Automatic Material System (AMS) Lite, opens up creative possibilities that were once available only to high-end machines. Priced at ₹49,990, the A1 Combo powered by WOL3D offers premium features at a budget-friendly cost, making it an attractive choice for anyone looking to enter the world of 3D printing or upgrade from older models. Here’s my experience with the Bambu Lab A1 Combo powered by WOL3D.

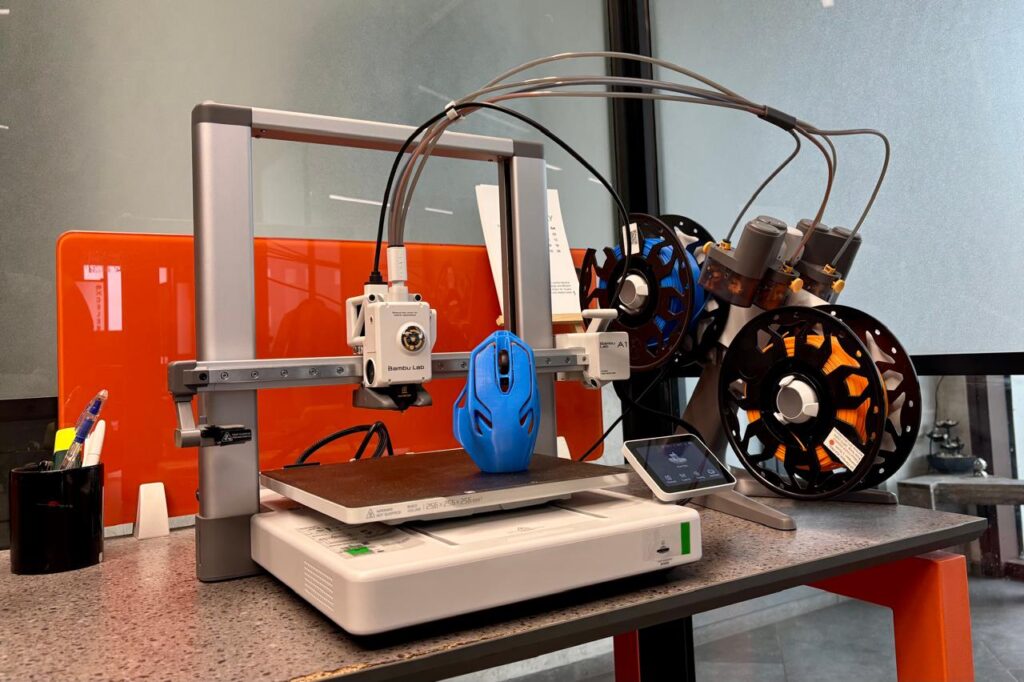

Design & Build

Assembling the Bambu Lab A1 Combo was a smooth experience that took me about an hour. The printer arrives pre-assembled primarily, and the included manual is clear and concise, guiding even beginners through the process with ease. The assembly steps include attaching the base of the AMS, securing a few screws, and connecting the PTFE tubes from the filament hub to the extruder. The manual’s diagrams and instructions were straightforward, making the assembly feel like a fun and manageable project rather than a daunting task. For someone upgrading from a printer like the Creality Ender 3 V2, which required hours of tinkering, this was a refreshing change.

The build quality of the A1 Combo is exceptional. Its unibody frame, featuring linear rods for the X-axis and metal rollers for the Y-axis, feels premium and robust, ensuring stability during high-speed prints. The all-metal hotend is capable of reaching temperatures of up to 300°C, which adds to its durability and ensures compatibility with a wide range of filaments. However, the AMS Lite, which enables multi-colour printing, significantly increases the printer’s footprint. The printer itself measures 385 x 410 x 430 mm (15 x 16 x 16.9 in) and requires additional horizontal space for the AMS Lite, which sits beside it. This setup might be a challenge for those with limited desk space, but the trade-off is worth it for the multi-colour functionality.

Performance

Getting started with the A1 Combo was remarkably intuitive, thanks to the integration of Bambu Studio on my Mac and the Bambu Handy mobile app. After connecting the printer to Wi-Fi, I could send print commands from anywhere as long as there was an internet connection. The setup process involved installing Bambu Studio, which handles slicing and print preparation, and using the Handy app for remote monitoring and control. The software ecosystem is user-friendly and polished, automatically calibrating settings such as Z-offset, bed levelling, and nozzle pressure for each print. This automation removed the guesswork I was used to with my Creality Ender 3 V2, where manual adjustments were often necessary.

The built-in camera is a standout feature, allowing me to monitor prints remotely and record timelapses. While the camera’s framerate is low (about 0.5 frames per second), it’s sufficient for checking print progress or capturing satisfying timelapse videos. For offline use, the colour touchscreen LCD on the printer provides an intuitive interface for controlling settings, starting prints, or checking the status, making it adaptable for users who prefer not to rely only on Wi-Fi connectivity.

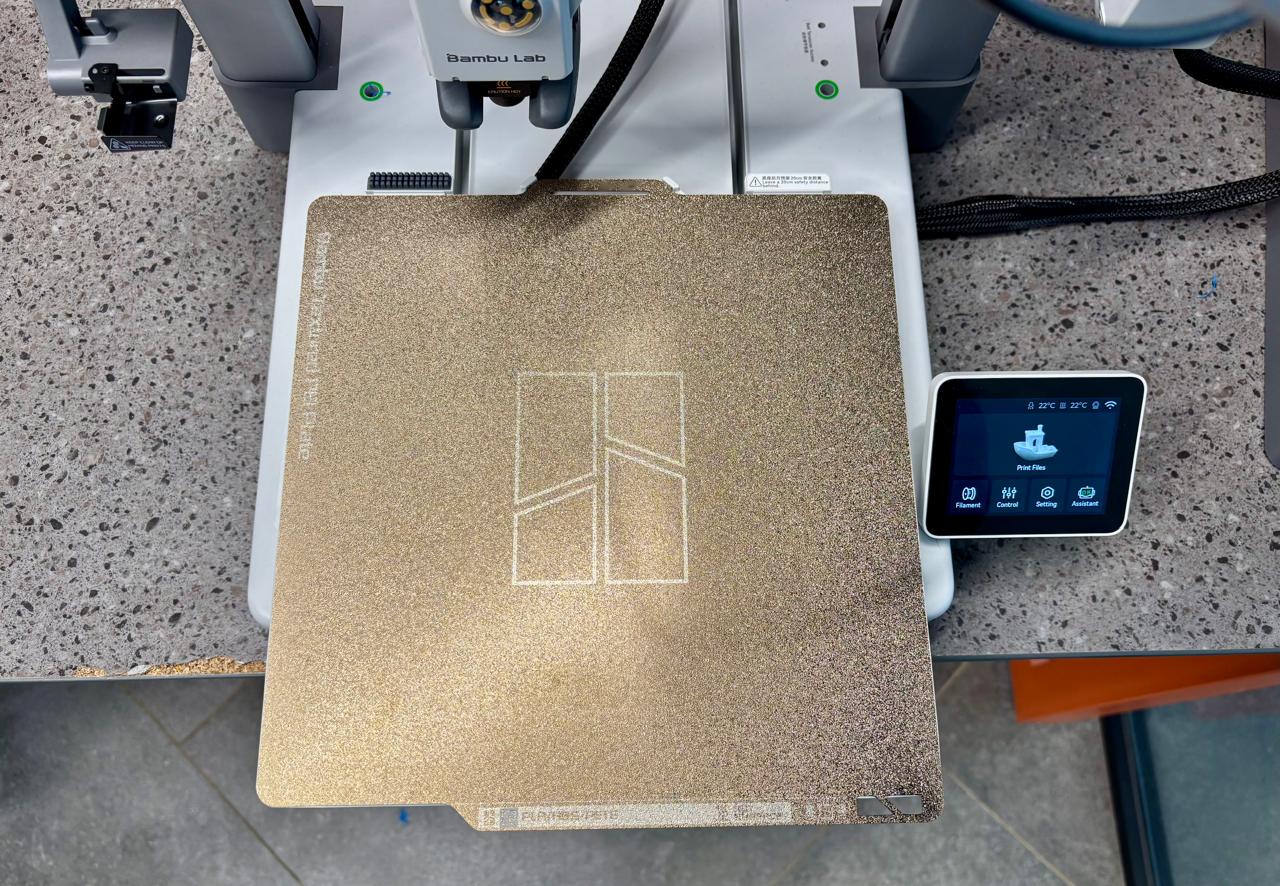

The removable textured PEI print bed is another highlight. It provides excellent adhesion for PLA prints, and its flexibility allows for easy removal; just bend the plate, and the print will pop off. This feature also allows for quick swapping of different plate textures or designs, streamlining the printing process for back-to-back projects. Compared to the Ender 3 V2’s often finicky bed adhesion, this was a significant upgrade.

Multi-Color Printing with AMS Lite

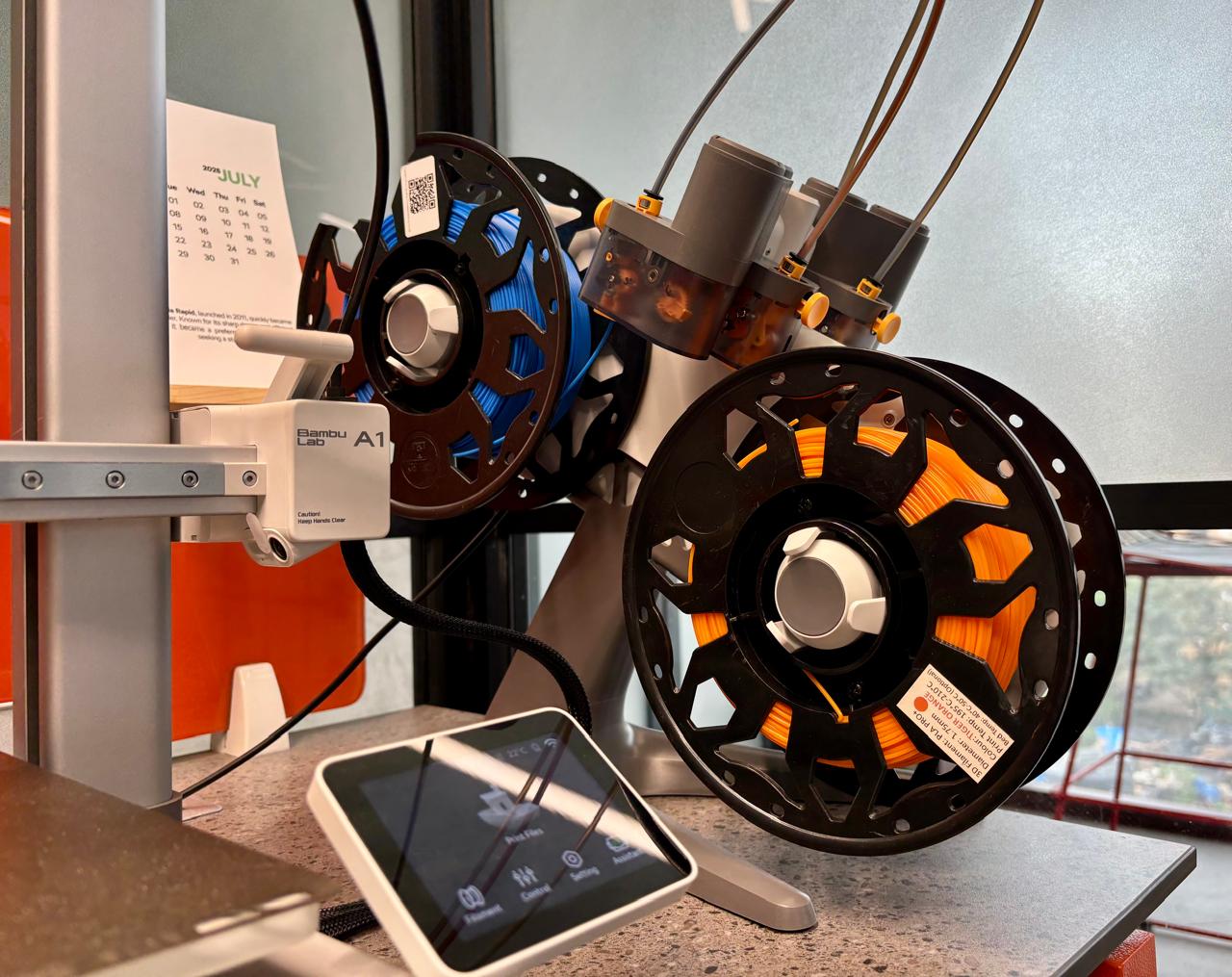

The AMS Lite is the star of the A1 Combo, enabling up to four-colour or multi-material prints. Setting it up was as simple as attaching the base, clicking in the spool holders, and connecting the PTFE tubes. The system utilizes RFID tags on Bambu Lab filament spools to automatically identify the filament type and color. We can also use other brands, such as Wol3D, but must manually set the colour. I experimented with multi-colour prints, including a Exhibit branded coasters, which showcased crisp colour transitions. However, multi-colour printing generates significant waste due to filament purges during colour changes, which can be reduced by careful print planning. The A1 Combo also supports single-color mode with a rear-mounted spool holder, offering flexibility for simpler projects.

Printing Experience

Over the past month, I have printed a variety of objects, ranging from functional items to decorative pieces. A custom shelf for my office desk printed flawlessly in PLA, showcasing the printer’s precision and capability to handle larger prints within its 256 x 256 x 256 mm build volume. I also created car models and name keychains for my colleagues, all of which received enthusiastic feedback for their detail and vibrant colours. The standout project was the mouse kit that came with the printer. Printing the outer shell and assembling it with the provided internals felt like a dream come true for any enthusiast. The final product was not only functional but also impressed my colleagues with its professional appearance and usability.

Most of the prints were precise and of high quality, thanks to the A1 Combo’s flow rate sensor, which ensured consistent extrusion. However, I did encounter a few failures, mainly due to power outages (which are a local issue) or incorrect print settings while experimenting with complex design. These issues were minor, and adjusting the settings in Bambu Studio resolved most problems. Compared to my Creality Ender 3 V2, which often required extensive tuning, the A1 Combo’s automatic calibration made the printing process feel effortless.

Speed and Filament Compatibility

The A1 Combo is incredibly fast, boasting a maximum print speed of 500 mm/s and an acceleration of 10,000 mm/s². In practice, I achieved speeds around 250 mm/s for most prints, which is significantly faster than the Ender 3 V2’s range of 60-100 mm/s. For instance, printing a 3D Benchy, a common benchmark model, took just 15 minutes compared to over an hour on my old printer. Remarkably, this speed did not compromise print quality, thanks to features like input shaping and vibration compensation.

I primarily used PLA filaments, which printed reliably and produced vibrant results. The A1 Combo also supports other materials such as PETG, TPU, and even ABS. However, its open-frame design makes ABS printing challenging without an enclosure, as warping can occur. For abrasive filaments like carbon fiber, it is recommended to use a hardened steel nozzle, which adds an extra cost but expands material options. The printer’s compatibility is impressive, but for now, I’ve focused on using PLA for its ease of use and reliability.

Noise Level

The A1 Combo is impressively quiet, with noise levels at or below 48 dB, thanks to silent motor drivers and a noise cancellation procedure during startup. In a quiet room, the cooling fans produce a soft hum, noticeable but not disruptive.

Aftersales and Filaments

WOL3D serves as the master distributor for Bambu Lab printers in India, offering dedicated after-sales support to ensure a seamless user experience. Their support includes troubleshooting assistance, spare parts availability, and guidance for optimal printer performance, making it easier for users to maintain and operate the A1 Combo over time. Additionally, the filaments used with the A1 Combo are produced in-house by WOL3D in India, utilizing sustainable corn starch as the primary material. These PLA filaments are biodegradable, aligning with environmentally conscious 3D printing practices and reducing the ecological footprint compared to traditional petroleum-based plastics. WOL3D’s in-house production ensures high-quality control, resulting in consistent filament diameter and vibrant colours that enhance print quality. Available in a wide range of colours, these filaments are optimized for the A1 Combo’s AMS Lite system, ensuring smooth feeding and reliable multi-colour printing. The use of corn starch not only supports sustainability but also maintains the strength and durability needed for both functional and decorative prints, making WOL3D filaments a perfect match for the A1 Combo’s capabilities.

1 Comment

Pingback: We Created a Best 3D Printing Product with Bambu Lab A1 Printer